● Highest loading capacity

● high holding torque

● high bending moment capacity

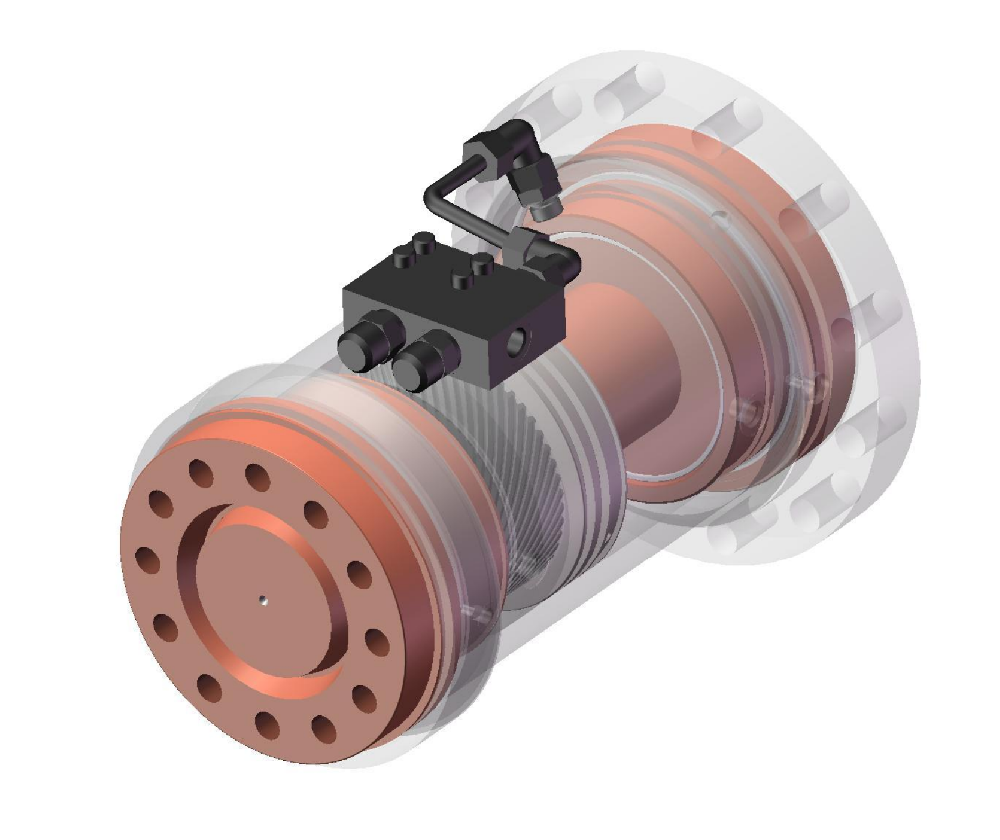

DH series can be used in a variety of industries as construction machinery, mining, military etc and is well know as its extremely sturdy and corrosion resistance, durability and flexibility, excellent performance especially in rough environmental condition.

DC series Specification | 20 | 30 | 50 | 70 | 100 | 140 | 180 | 240 | |||

Torque | |||||||||||

Drive | @3000psi | In-lb | 17000 | 25000 | 42000 | 65000 | 95000 | 125000 | 165000 | 215000 | |

@210bar | Nm | 1920 | 2820 | 4750 | 7340 | 10700 | 14100 | 18600 | 24300 | ||

Holding | In-lb | 430000 | 600000 | 106000 | 159000 | 230000 | 300000 | 398000 | 530000 | ||

Nm | 4900 | 6800 | 12000 | 18000 | 26000 | 34000 | 45000 | 60000 | |||

Maximum Moment Capacity | |||||||||||

Cantilever mount | In-lb | 45900 | 62500 | 105000 | 162000 | 261250 | 343750 | 495000 | 645000 | ||

Nm | 5200 | 7100 | 11900 | 18400 | 29500 | 38800 | 55900 | 72900 | |||

Straddle mount (for SS) | In-lb | 119000 | 150000 | 273000 | 423000 | 665000 | 875000 | 1155000 | 1505000 | ||

Nm | 13400 | 16900 | 30800 | 47800 | 75100 | 98900 | 130000 | 170000 | |||

Capacity | |||||||||||

Radial | lb | 4000 | 5000 | 8000 | 11000 | 15000 | 18000 | 22000 | 26000 | ||

kg | 1800 | 2300 | 3600 | 5000 | 6800 | 8200 | 10000 | 12000 | |||

Axial | lb | 3000 | 4000 | 6000 | 8000 | 10000 | 13000 | 15000 | 18000 | ||

kg | 1400 | 1800 | 2300 | 2700 | 3600 | 4500 | 5900 | 6800 | |||

Displacement | |||||||||||

180° | in³ | 30 | 42 | 72 | 114 | 163 | 215 | 283 | 366 | ||

cm³ | 485 | 691 | 1190 | 1865 | 2670 | 3530 | 4650 | 6000 | |||

360° | in³ | 60 | 85 | 144 | 228 | 327 | 432 | 569 | 730 | ||

cm³ | 961 | 1385 | 2366 | 3735 | 5365 | 7070 | 9315 | 11960 | |||

Weight | |||||||||||

180° | lb | 82 | 108 | 170 | 249 | 364 | 494 | 631 | 851 | ||

kg | 37 | 49 | 77 | 113 | 165 | 224 | 286 | 368 | |||

360° | lb | 108 | 146 | 223 | 315 | 452 | 653 | 829 | 1076 | ||

kg | 49 | 66 | 101 | 143 | 205 | 296 | 376 | 488 | |||

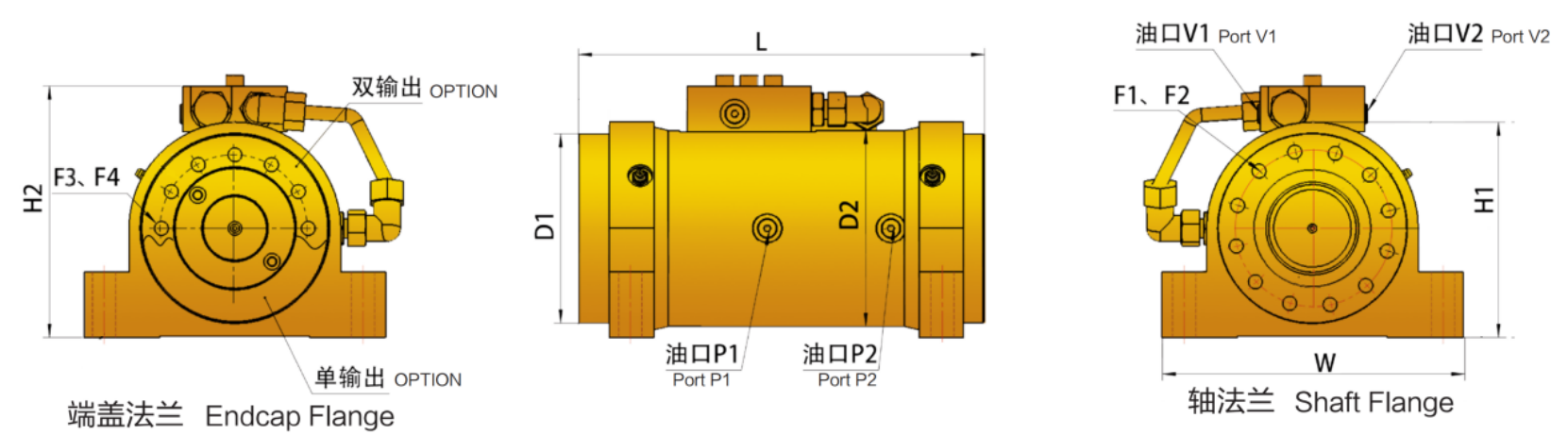

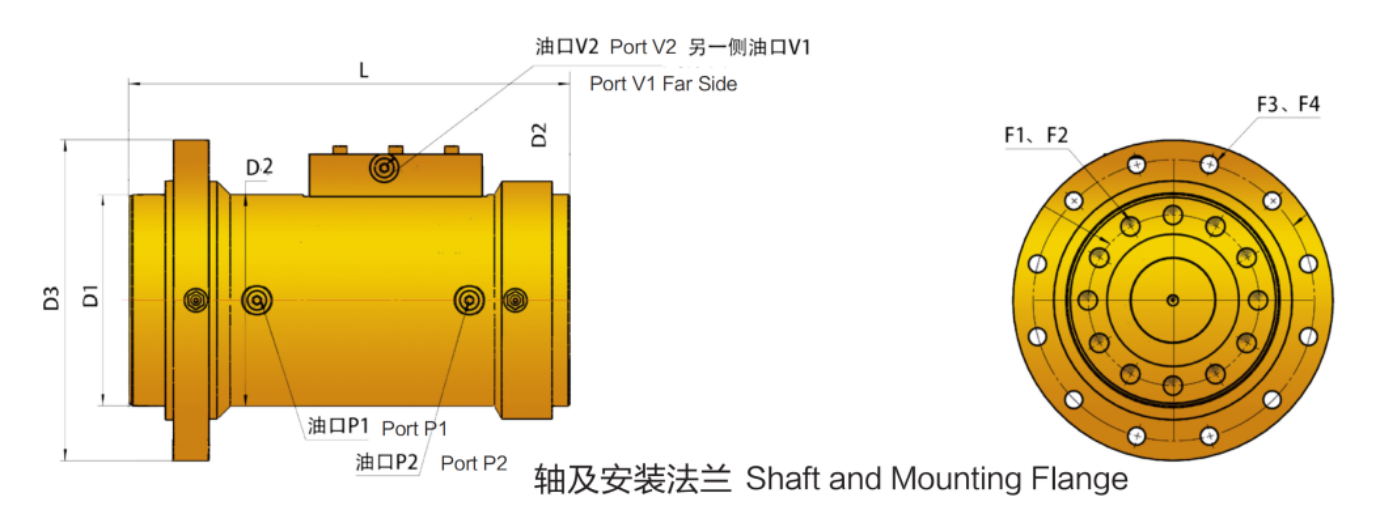

Dimension | |||||||||||

L(Length) | 180° | in/mm | 11.7/298 | 12.7/323 | 14.4/365 | 16.2/413 | 18.7/475 | 20.6/524 | 21.8/554 | 23.6/600 | |

360° | in/mm | 16.8/427 | 18.5/470 | 21.2/538 | 24.2/615 | 27.8/705 | 30.6/776 | 32.9/836 | 35.7/906 | ||

D1(Diameter) | in/mm | 5.5/139 | 6.1/155 | 7.2/183 | 8.2/209 | 9.2/234 | 10.3/263 | 11.3/288 | 12.2/310 | ||

D2(Diameter) | 5.5/139 | 6/152 | 7/178 | 8/203 | 9/229 | 10/254 | 11/279 | 12/406 | |||

D3(Diameter) | 7.9/200 | 9.3/235 | 11/280 | 12.4/315 | 14/355 | 15.6/396 | 17.4/442 | 18.7/475 | |||

F1,F2 | inch | 12X3/8-16 | 12X1/2-13 | 12X5/8-11 | 12X1/2-13 X0.75 | 12X3/4-10 | 12X7/8-9 | 12X1-8 | 12X1-8 | ||

Ø4.25 B.C. | Ø4.75 B.C. | Ø5.25 B.C. | Ø6.00 B.C. | Ø6.75 B.C. | Ø7.5 B.C. | Ø8.25 B.C. | Ø9.0 B.C. | ||||

metric | 12XM10-1.5 | 12XM12-1.75 | 12XM16-2 | 12XM20-2.5 | 12XM22-2.5 | 12XM24-3 | 12XM24-3 | 12XM27-3 | |||

Ø108 B.C. | Ø108 B.C. | Ø120 B.C. | Ø133 B.C. | Ø150 B.C. | Ø170 B.C. | Ø190 B.C. | Ø210 B.C. | ||||

F3,F4(foot mounted) | inch | 12X1/2-13 | 12X5/8-11 | 12X3/4-10 | 12X7/8-9 | 12X1-8 | 12X1 1/8-7 | 12X1 1/8-7 | 12X1 1/4-7 | ||

Ø3.9 B.C. | Ø4.2 B.C. | Ø4.7 B.C. | Ø5.2 B.C. | Ø5.7 B.C. | Ø6.2 B.C. | Ø6.7 B.C. | Ø7.2 B.C. | ||||

metric | 12XM12-1.75 | 12XM16-2 | 12XM20-2.5 | 12XM22-2.5 | 12XM24-3 | 12XM27-3 | 12XM27-3 | 12XM30-3.5 | |||

Ø99 B.C. | Ø106 B.C. | Ø118 B.C. | Ø131 B.C. | Ø144 B.C. | Ø156 B.C. | Ø169 B.C. | Ø182 B.C. | ||||

F3,F4(Flange mounted) | inch | 12X3/8 | 12X1/2 | 12X5/8 | 12X3/4 | 12X7/8X0 | 12X1 | 12X1 1/8 | 12X1 1/4 | ||

Ø6.9 B.C. | Ø8.1 B.C. | Ø9.6 B.C. | Ø10.8 B.C. | Ø12.2 B.C | Ø13.6 B.C. | Ø15.0 B.C | Ø16.1 B.C | ||||

metric | 12XM10 | 12XM12 | 12XM16 | 12XM20 | 12XM22 | 12XM24 | 12XM27 | 12XM30 | |||

Ø175 B.C. | Ø205 B.C. | Ø245 B.C. | Ø275 B.C. | Ø310 B.C. | Ø345 B.C. | Ø380 B.C. | Ø410 B.C. | ||||